Breakthrough in Type-3 Aluminium Fully-wrapped Composite Cylinders

Capping Cost of manufacture of Type-3 Aluminium Fully-wrapped Composite Cylinders now possible!

Don’t get lost in fumes – know how, and how much you can save!

Understand future fuel economy standards that automakers the world are improving upon!

US, EU, and China have already started working to cut their urban air pollution by aggressively promoting alternative fuel technologies – including electric cars – while implementing stricter fuel-economy standards over the next few years. With USA setting their goal for 2025 and China, a very close 2017.

India’s regulatory agencies will introduce stricter legislations any time in the near future, and require all states to adapt and adopt in a very short time. This will be in line with India’s target to lower emissions by 33-35% by 2030 below the 2005 levels, and may invest $834B in mitigation for upstream policies like renewable energy efficiency, transport, smart cities, etc. This is part of Government of India’s INDC (Intended Nationally Determined Contribution) in response to decisions 1/CP.19 and 1/CP.20 of the Conference of Parties at United Nations Framework Convention on Climate Change (UNFCCC).

CAFE – or Corporate Average Fuel Economy – standards

Goal: “60 mpg by 2025” – Quite a number of hybrid autos manufacutured globally either meet or beat the target in 2016

Unfortunately, cars are expected to achieve higher fuel efficiency numbers in a smaller range, whereas trucks have a broad range and relatively lower targets.

The challenge for trucks

Though trucks relying on diesel as their sole fuel, can save by switching to CNG or LNG, they still have to rely on the heavier Type-1 Steel Cylinders. This means the trucks end up hauling dead weight along with fuel and payload.

The possible solution

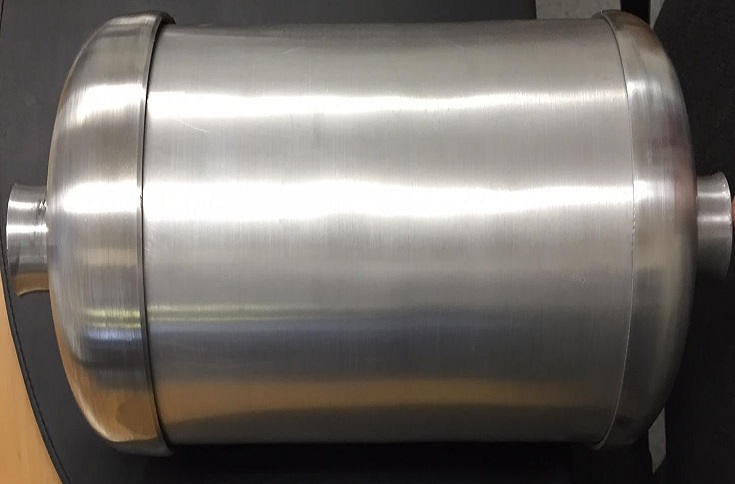

The issue of having to carry dead-weight can be addressed by switching to lightweight Type-3 Aluminium, Fully Wrapped Composite Cylinders that are strong and can be loaded to their service pressure rating, while weighing half as much as Type-1 cylinders! However, Type-3 Aluminium Composite Cylinders could not make an entry in the auto inudstry in India because of market pricing.

The issue

Currently, there are only five active, global facilities in the world manufacturing Type-3 Cylinders. None of them have been able to bring down the cost of Type-3 Cylinders as compared with Type-1 Cylinders, thus being unable to break the ice vis-a-vis introducing these efficient cylinders into the auto industry. Type-3 Cylinders typically cost five to six times the cost of Type-1 Cylinders because of three main factors:

1) Cost of Alumunium Alloy

2) Considerable CapEx and energy involved in flow-forming seamless tubes to form a cylinder to support pressure required

3) Cost of Composite filament

The solution

An innovative design and process that reduces dependency during the manufacture of the Aluminium Allow Liner.

Shri Gopala Vinjamuri came up with an innovative liner design that reduces the CapEx and energy requirement in the front-end process requirement of manufacturing a liner.

Shri Gopala Vinjamuri has over forty years’ experience in pressure vessel design of high pressure filament-wound composite cylinders, stress analysis, fracture mechanics and fatigue evaluation of pressure vessels and pipeline systems along with compliance evaluation of Federal, Hazardous Materials and Pipeline Safety regulations and understands both line and composite technology along with regulatory requirement.

His design is Patented in the US and patents have been applied for in India and the European Union.

(Video works best in Internet Explorer)

We are now researching in further eliminating energy dependencies that will help in further reducing energy dependencies and expanding the dimensions of Type-3 Aluminium Composite Cylinders. This will help us work out of the box and help other ancillary industries take advantage of Type-3 Cylinders.

We are currently working on a mileage estimator and a cost configurator for highway conditions in India – please write to us (business.development@vinjamuri-innovations.com) if you want to contribute, participate or want to know more about it!